1. When adding ink, do not lift the external supply box very high for the convenience. It will cause pressure imbalance, and the ink will overflow from the nozzle and cause the printhead to short-circuit and burn the main board.

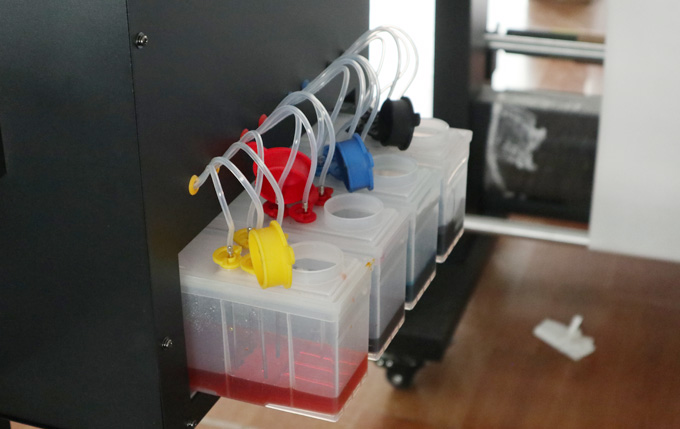

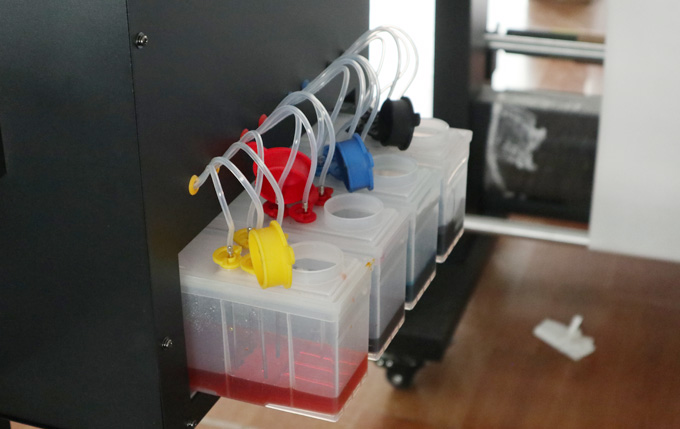

2.Before adding ink, close the vent hole of the ink supply system first, then add ink to the ink injection hole, and then restore the original state, that is, plug the vent hole after the ink hole is plugged, remember that there cannot be too much ink in the vent chamber.If the ink level on the vent hole is too high, the ink pressure will change and the inkjet will not be smooth.

3. Before adding ink to the skycolor uv flatbed printing machine that integrates the print head and ink cartridges, it is best to take the ink supply system together with the ink cartridges out of the machine and then add ink. The pressure is always balanced during the use of the continuous ink supply system. Suddenly adding ink to the outer cartridge will cause an imbalance of pressure for a short time. There will be ink overflow from the nozzle and short circuit of the cartridge circuit, so it is recommended that you remove the continuous ink supply system and add ink.After adding, wait until the pressure between the inner box and the outer box is balanced before using it on the machine. If the ink overflows, you can clean the nozzle ink with toilet paper until it is balanced.

4. Choose high-quality and compatible ink to add. The key point of whether the ink supply system is easy to use is ink. After adding ink, printing often causes clogging, disconnection, and color cast, so users choose high-quality ink as much as possible. In addition to high quality, it is also necessary to pay attention to whether the added ink is compatible with the original residual ink. Many customers have corrosion and agglomeration of the nozzle due to the reaction of the two inks. Recommend everyone to choose the original ink.