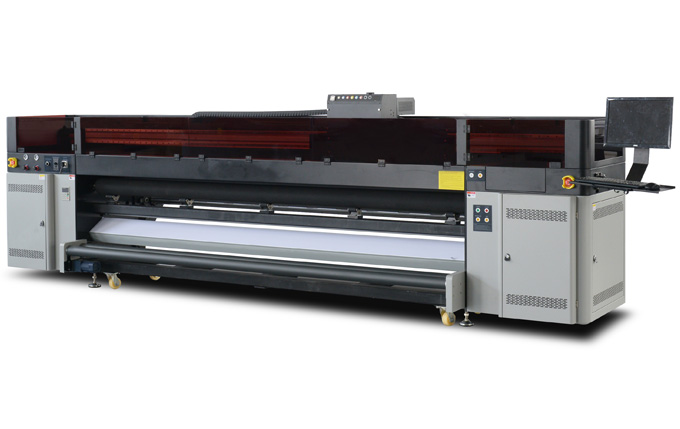

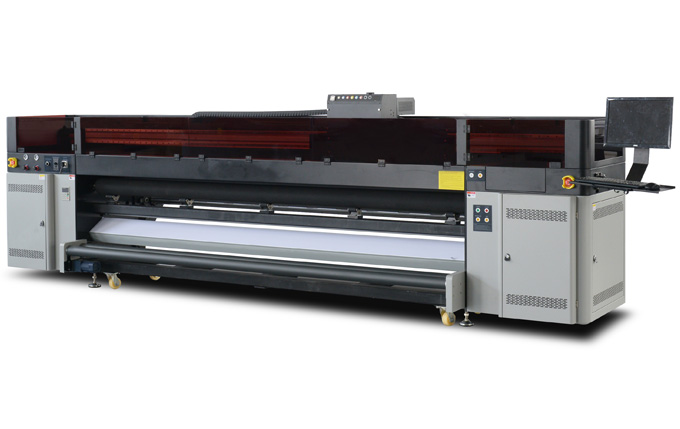

Normal work of

uv roll to roll printer is inseparable from high-quality ink, but what should be paid attention to in process of ink purchase and use? Skycolor uv printer manufacturers have summarized two points for your reference.

1.The first is ink storage skills of Skycolor uv printer ink. Storage environment of uv printer ink should be consistent with use environment. Especially in winter and summer, temperature of most storage rooms and temperature of working environment are very different, so uv roll to roll printer ink has unsmooth phenomenon affects work efficiency and even waste products. Solution is to bring uv printer ink to use environment a few hours in advance, and wait until ink temperature reaches required temperature before using it.

2.There is also a bad habit that in order to reduce working capital, users will order next batch of ink after using up ink. This will reduce production efficiency, so correct way is to prepare more ink. In addition, new ink should be used immediately on uv roll to roll printer to determine whether new ink is easy to use. If any problem is found, replace and exchange with new ink immediately. If there is no problem with new ink, old ink should be used up first to prevent old ink from exceeding its shelf life.

Zhengzhou New Century Digital Technology Co., Ltd (Skycolor UV Printer:

www.skycoloruv.com) is a professional high-tech enterprise engaged in R&D, production and sale of skycolor uv flatbed printer,skycolor uv roll to roll printer and related consumables.

Over the years,company has accumulated rich experience in digital uv printing field and gathered a batch of employees with professional skills. With high product quality and standardized service system,company has won high reputation from global market and trust of cooperated units.