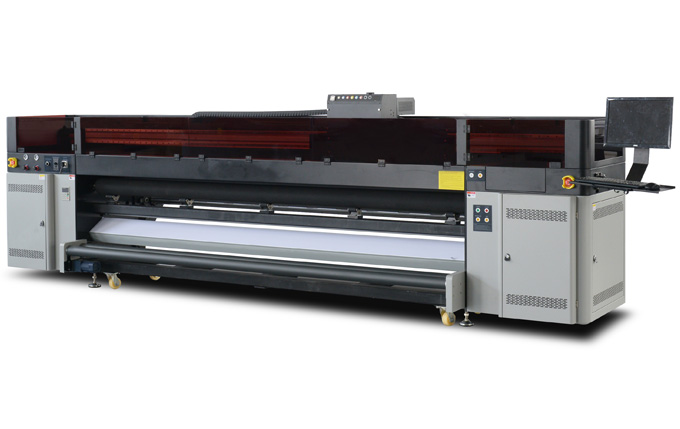

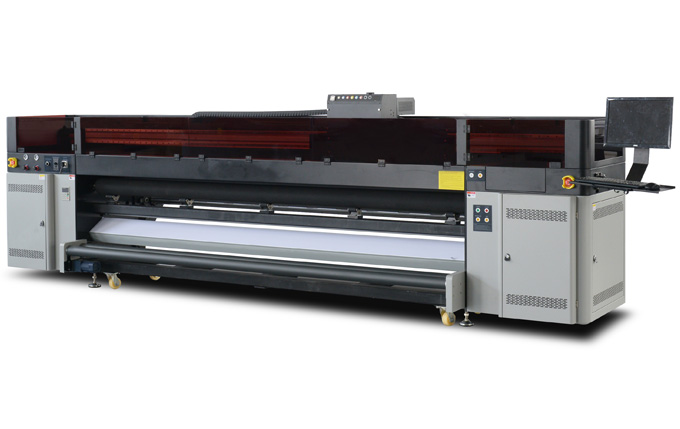

If you want a good

uv leather printer to maximize its efficiency, regular operation and maintenance are indispensable. Now follow the skycolor uv group to understand the

daily operation and maintenance of the uv leather printer!

1.The correct switch operation provides a stable working voltage for the uv leather printer. In the daily maintenance operations of related machine accessories, pay attention to shut down and power off before performing related maintenance operations. Do not perform live operations to avoid damage to the printer and accessories. Live operations are more likely to cause safety problems such as electric shock.

1) Don't try to disassemble and repair the uv leather printer by yourself

2) If the printer produces abnormal noise, smoke, temperature rise, strange smell or other abnormal functions, turn off the power immediately, unplug the power cord, and contact the customer service.

3) Do not use flammable objects or similar products around the uv leather printer.

4) Before moving the uv leather printer, make sure to turn off the power and unplug the power cord.

5) Always use the power switch to turn off the uv leather printer. When this button is pressed, the power will be cut off. Before the power is cut off, do not unplug the printer plug or data cable.

6) Make sure the print head is fixed in the initial position before transporting the printer.

7) Do not engage in any cleaning and maintenance work before turning off the power and unplugging the power socket.

8) When the uv leather printer is operating, do not touch any power components and print head.

9)At least once a year, remove dust and debris around the power plug and power socket.

2. Provide a good working environment for the uv leather printer. Pay attention to the temperature and humidity. For example, the suitable working environment for the uv leather printer requires a room temperature between 15-35℃. And it is better to keep the air humidity at 35%-65%.Connect the ground wire to the uv leather printer to release the static electricity generated by the printing machine to avoid damaging the print head, the control main board and related electronic components.