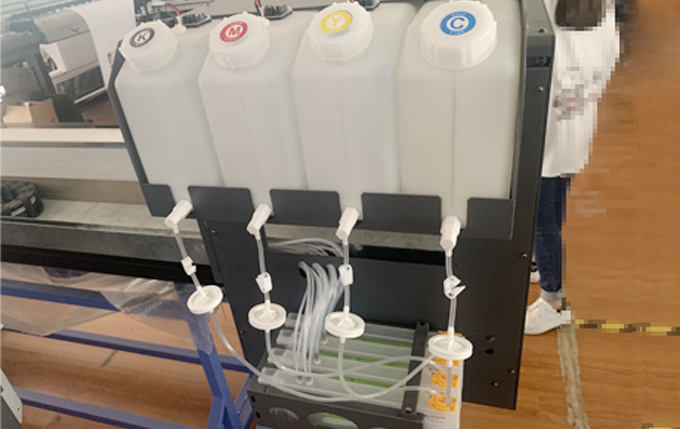

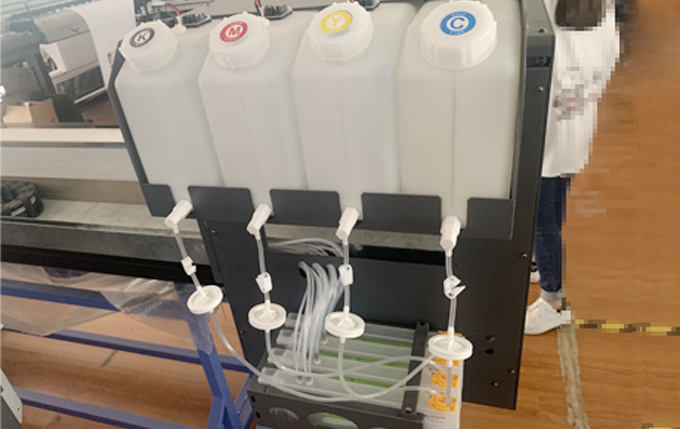

The continuous ink supply system is the most commonly used ink supply method for wide format printers. In particular, all piezoelectric printers basically use this ink supply system. Does continuous ink supply require ink? What are the requirements? In addition to meeting the other basic characteristics of ink, the continuous supply ink focuses on analyzing the characteristics of ink printing fluency, good ink stability, and low loss of the print head for long-term printing.

Ink fluency: mainly related to the compatibility of the sponge and other materials in the ink cartridge, and the structure of the ink cartridge. The characteristics of ink viscosity, surface tension, etc. are related to the ink absorption and ink release of the sponge. During the high-intensity printing process, there is a disconnection phenomenon that occurs because the viscosity of the ink is too large and the sponge cannot release ink smoothly.In this regard, the ink and the sponge are more related.

Ink stability: In the production process of ink color bases (dye, pigment), due to impure raw materials or intermediate products generated by synthesis reaction, such as soluble organic polymer tar, if not removed by special methods, the ink during long-term use, chemical reactions may occur, flocculation deposits occur, and it is easy to accumulate on the filter of the ink cartridge. For high-intensity printing with continuous ink supply, if the ink stability is not good, the printing will be disconnected. Sometimes cleaning can solve it. If it accumulates too much, replace the ink cartridge or use a special tar-soluble one for the print head.

Long-term printing has low loss to the print head: this aspect is analyzed from the salt content (conductivity) of the ink. The ink must be desalted to control the salt content. In addition, the added solvent in the ink, harmful metal ions and organic impurities should also be controlled. If the conductivity of the ink is too high, it contains too much inorganic salt. If the content of the chloride ion combined with the inorganic salt is too high, there is potential corrosiveness to the print head; in addition, the ink system will cause electrochemical reactions, may cause the dye to crystallize out and accumulate on the filter screen, which may cause nozzle missing or block the print head.

The above points place strict requirements on the continuous ink supply with high printing intensity, which also shows that the selection of ink should be tested in many ways.It is recommended that you buy the original ink provided by the printing machine manufacturer, or the ink specified by the manufacturer, so as to ensure the print quality and reduce the risk of clogging the nozzle.